Impressive Info About How To Spot Weld

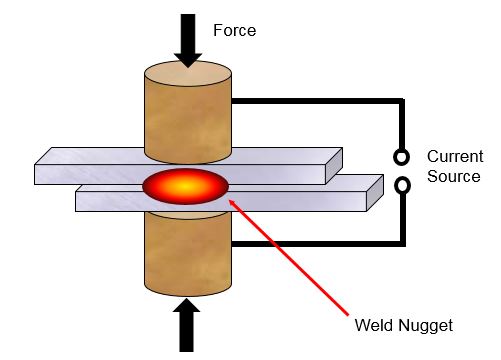

During the spot welding process, a very high amount of heat is generated at the region of the metal joint.

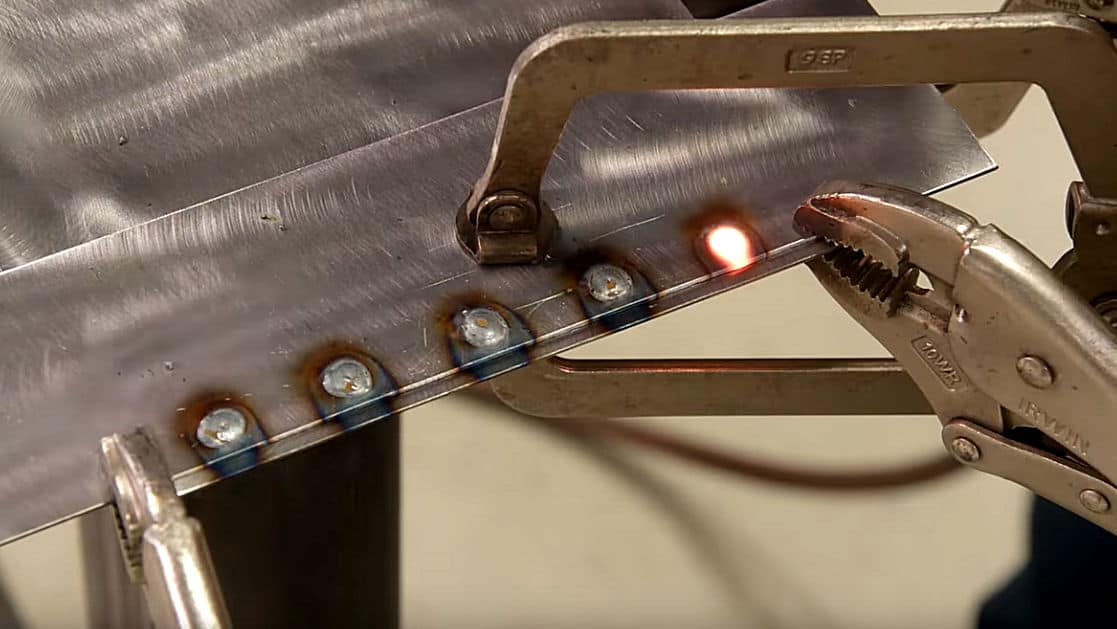

How to spot weld. Spot welding is primarily used for joining parts that are normally up to 3 mm in thickness. The spot weld symbol is indicated by a circle, so it’s pretty easy to understand. I'm simply a self taught welder and thought i could pass on a tip that has helped me along the way.

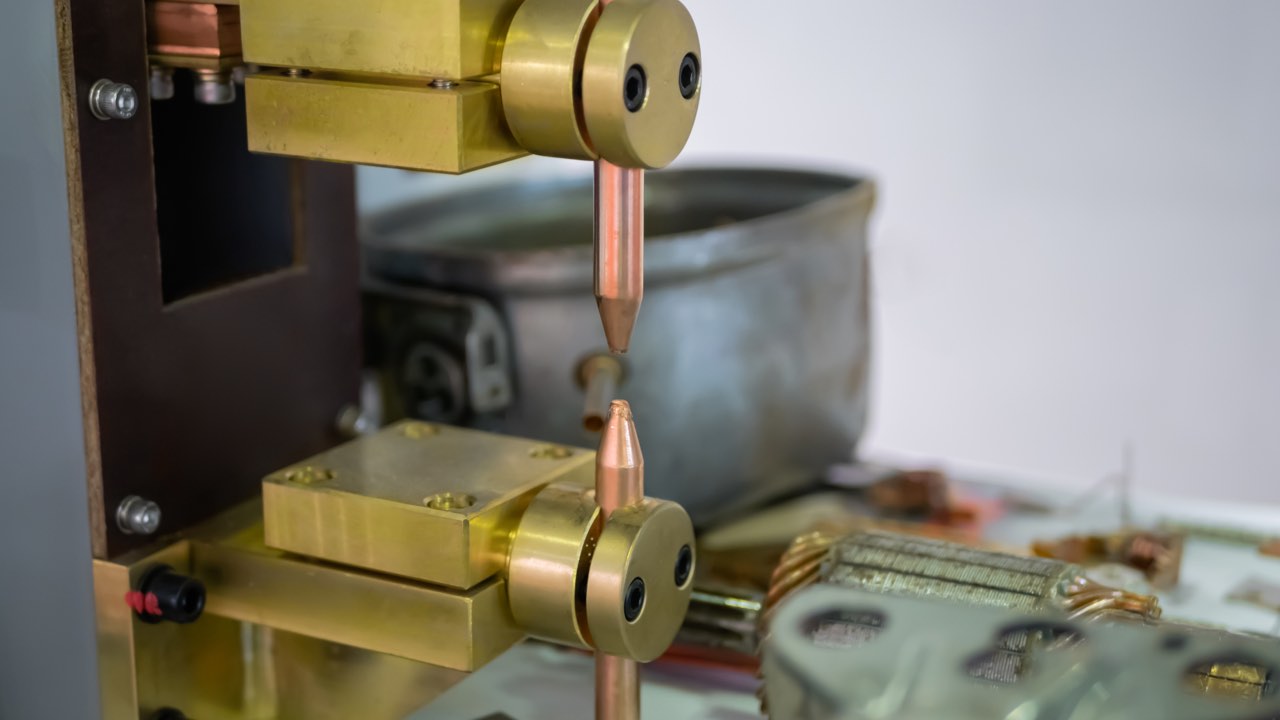

A current is passed between two electrodes through multiple sheets of metal. Let's talk about how to remove spot welds, because it's more difficult than it first seems!please help support the channel: Plug welds or rosette welds made with a mig welder are standa.

To calculate the nugget size all are calculated using the same simple average of the dimensions as shown. Spot welding (also known as resistance spot welding) is a resistance welding process. Weld nugget size is the normal specified.

Pro welders probably spot wel. One of the easiest spot welders to use in the market is the. The nuggets may not be perfect circles.

This type of electrical power is wanted for the big output current that spot welding requires. Use three phase electrical energy to spot weld aluminum. To produce a spot weld, use a pair of clamps to clamp the work pieces together and apply the necessary current.

The terms “spot welds” and “rosette welds” are often interchanged in the diy automotive world but they are two different things. It can be placed below, above, or right on the reference line. If you have the spot weld symbol on.